Services

Engineering services for industrial partners

Our services

Delivering reliable results

We provide cutting-edge 3D CAD design services tailored to your specific needs. Our expert team leverages the latest softwares and techniques to create detailed, accurate, and innovative 3D models for diverse applications. From concept to final production-ready designs, we ensure efficiency, quality, and seamless collaboration throughout the process. Let us transform your ideas into reality.

+36-30-983-4928

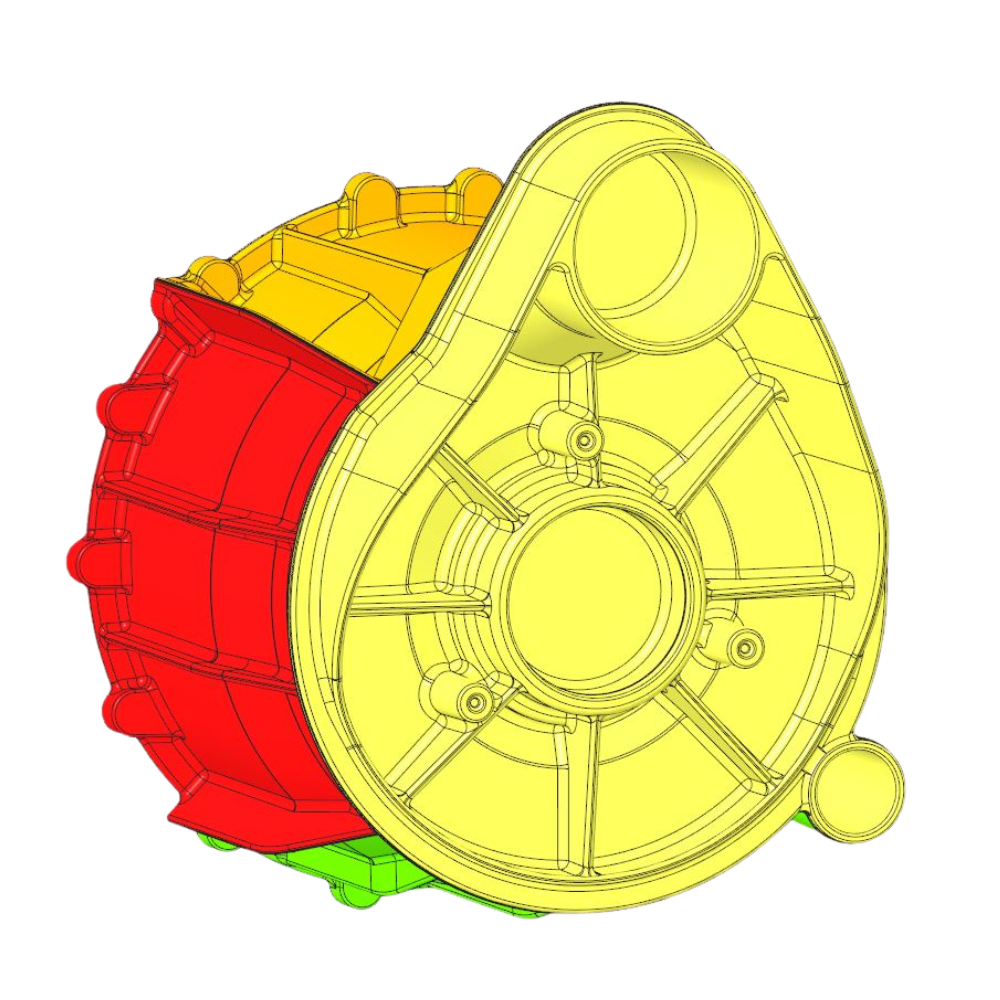

Our component design process prioritises efficiency and flexibility. We begin by establishing key parameters to create a solid baseline such as nominal wall thickness, draft angles, machining allowances and the initial tooling concept. This approach streamlines the design process, significantly reducing development time. Furthermore, the flexibility of this method allows for on-the-fly adjustments to key characteristics without disrupting the design process, ensuring rapid iteration and efficient design optimisation.

Our process starts by refining the tooling concept from the initial component design. We meticulously address potential undercuts and ensure optimal wall thickness in the tooling, incorporating efficient cooling channels where applicable. Our innovative approach uses a mathematical model to generate the runner geometry, unlike traditional methods. This ensures minimal material usage and highly efficient material flow. A key advantage is the model’s ability to self-adjust based on simulation results, eliminating the need for manual recreation. Simply adjust the initial parameters, and the model regenerates accordingly. The result is a robust, efficient and reliable tooling concept, ready for immediate tool development.

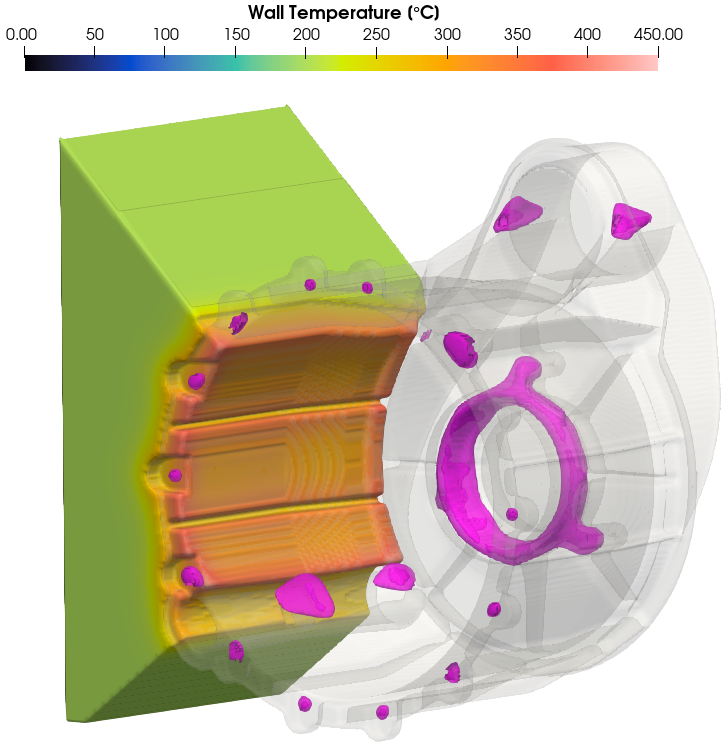

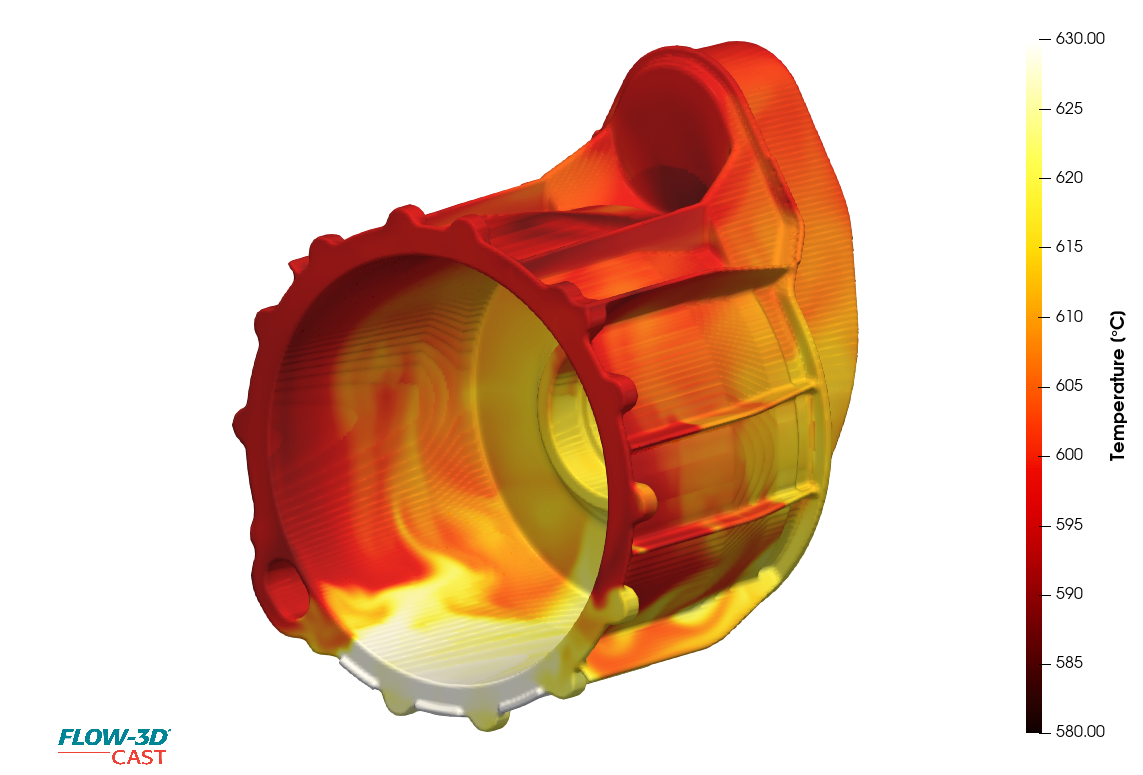

Our advanced simulation solutions provide comprehensive analysis of the casting process. We offer detailed filling simulations, accurately modelling the material flow to identify potential issues such as air entrapment. Our simulations incorporate solidification analysis to predict shrinkage porosity and identify areas prone to defects. Furthermore, our thermal die cyclic simulations provide insights into temperature fluctuations and potential hotspots within the mold. This approach allows for the proactive identification and mitigation of potential issues, ensuring optimal part quality and production efficiency.